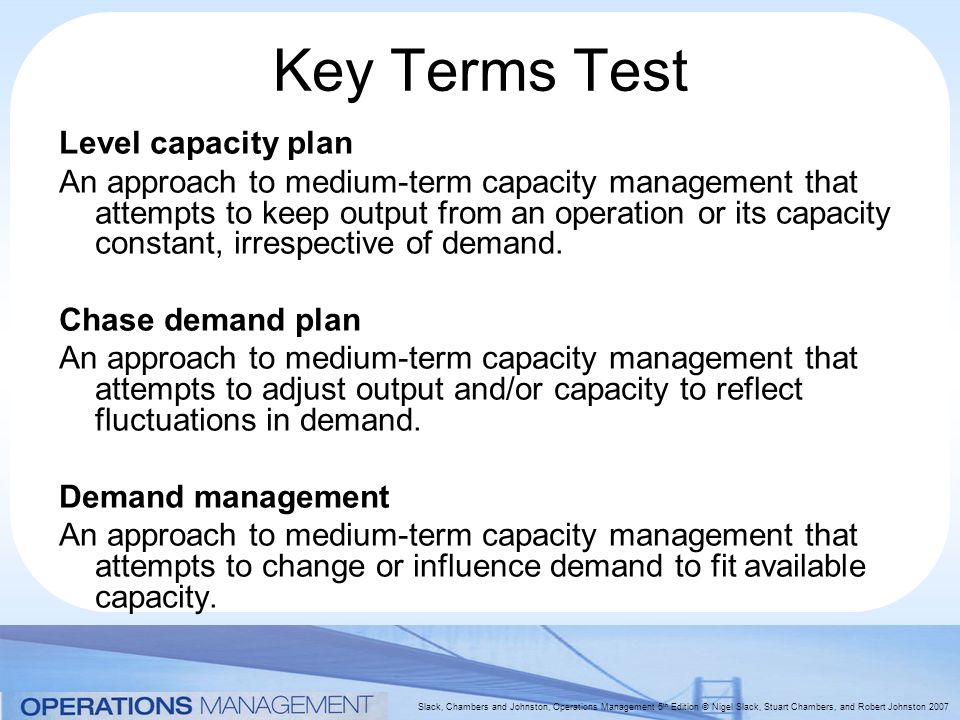

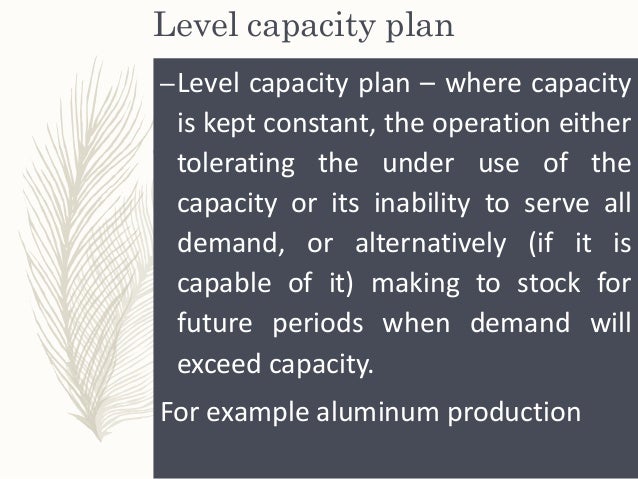

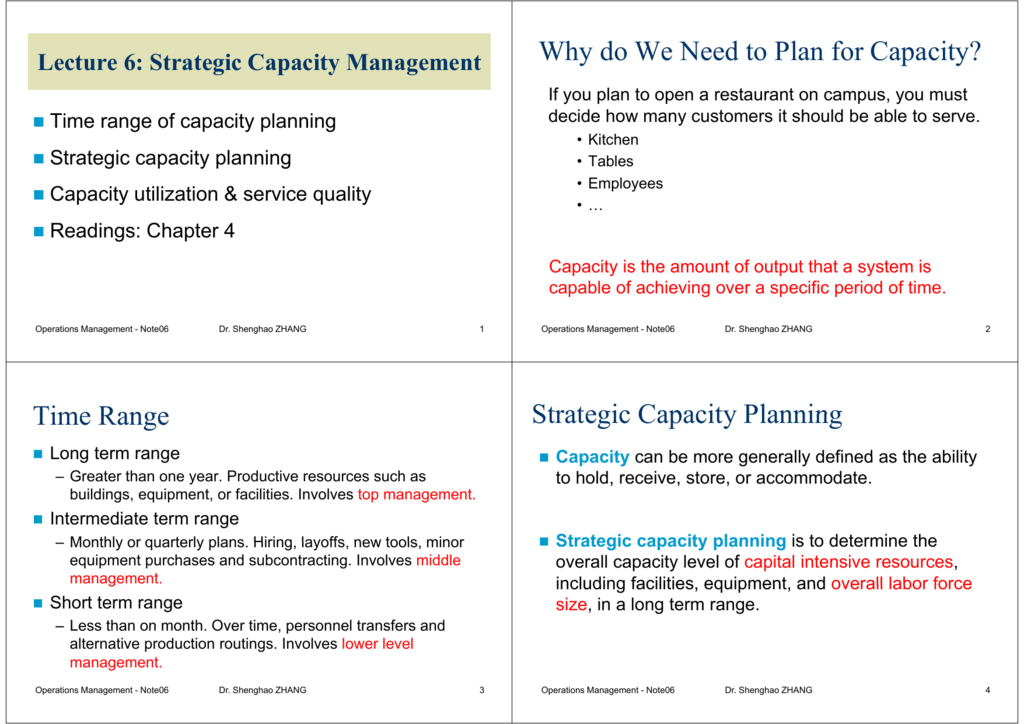

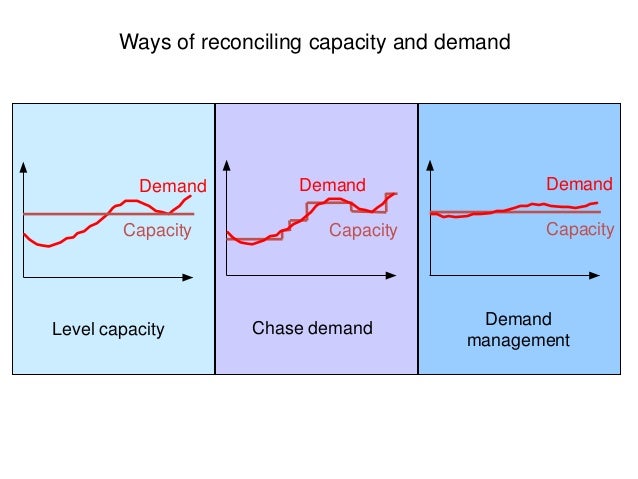

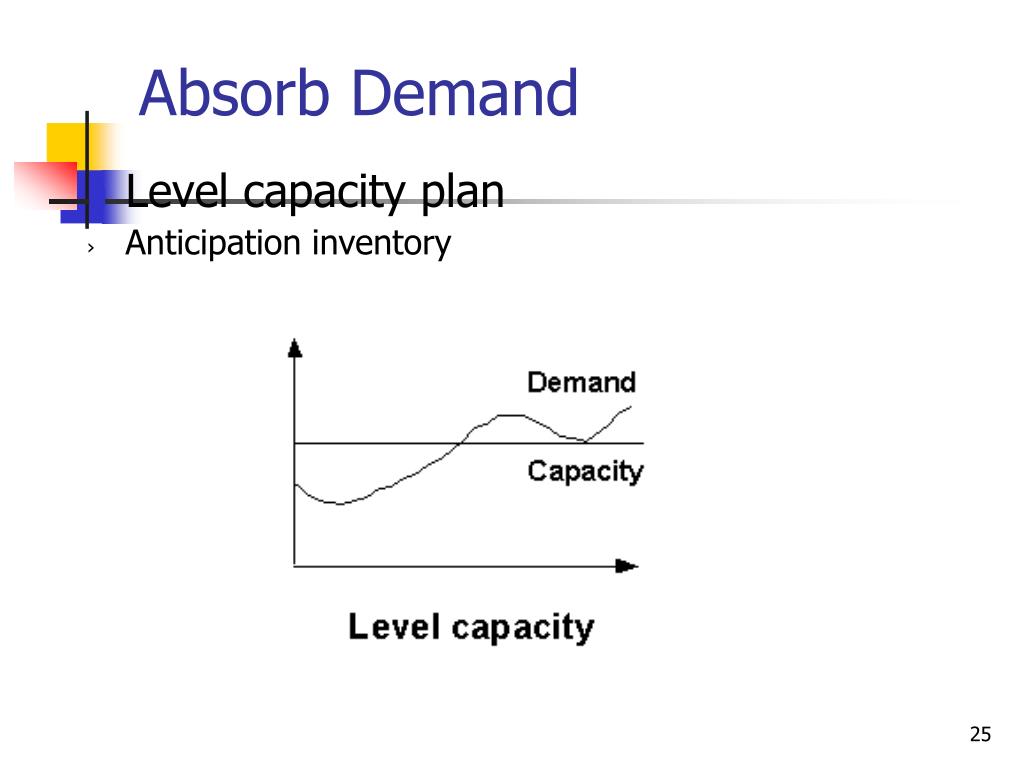

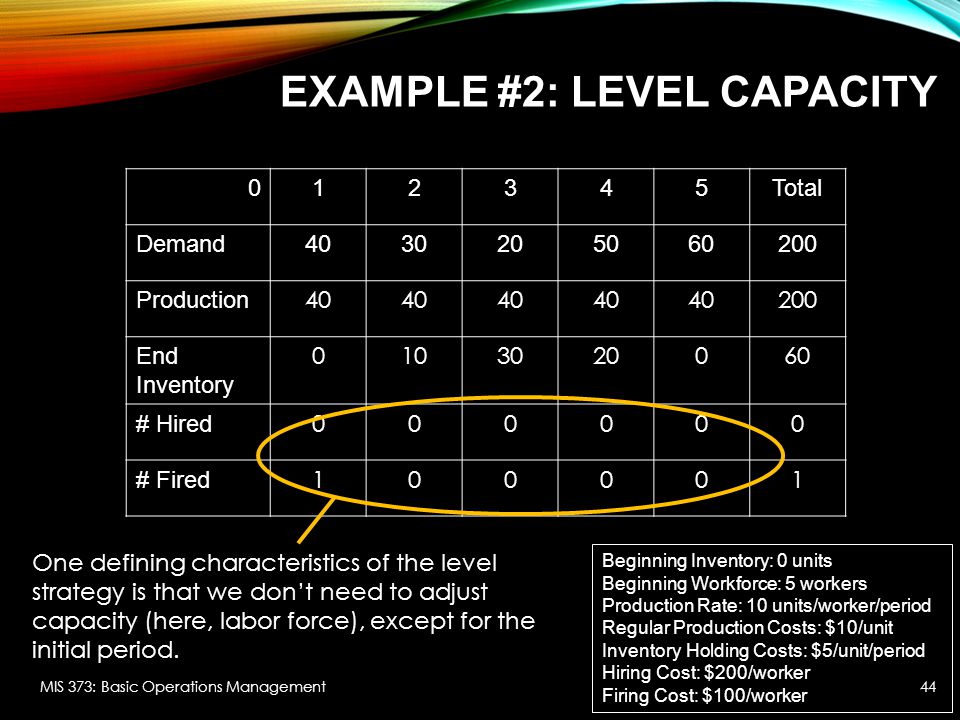

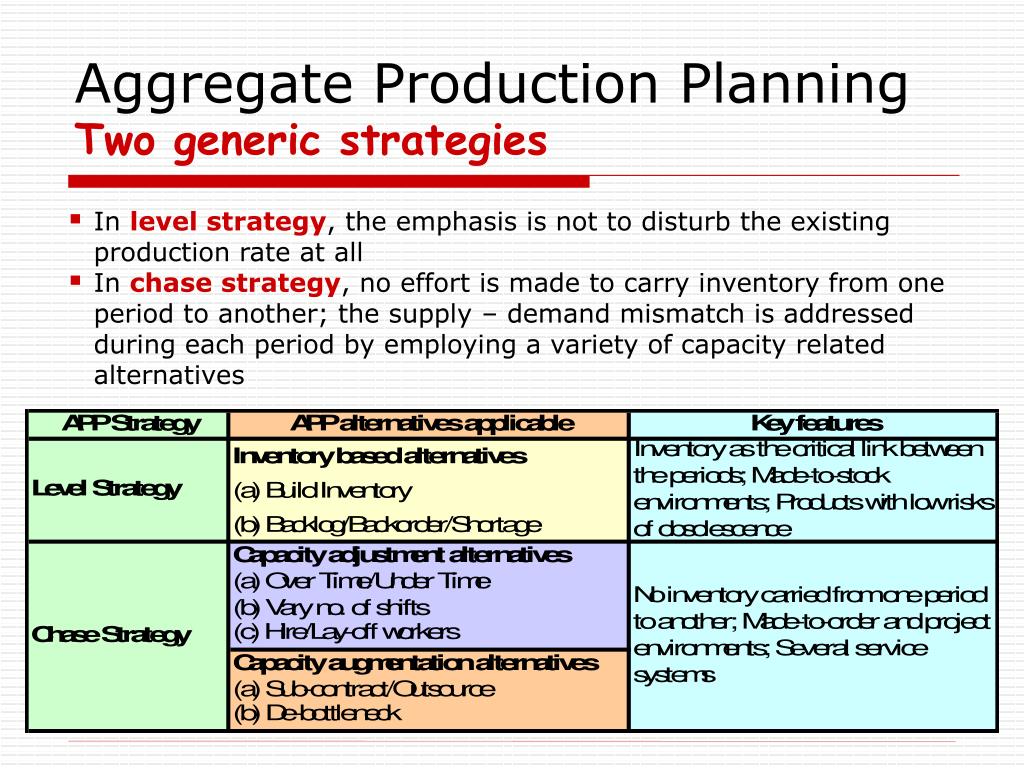

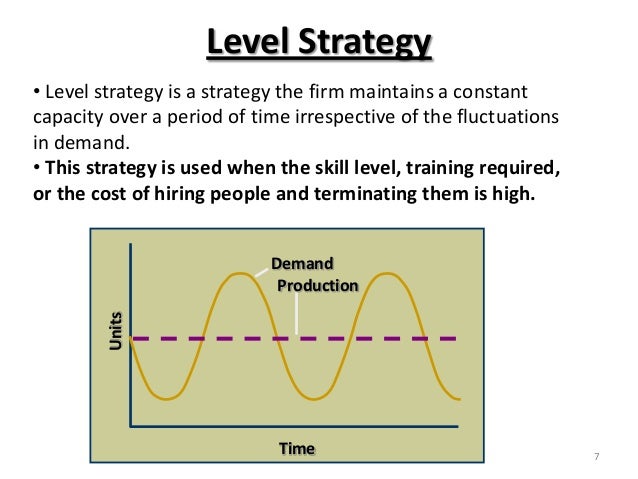

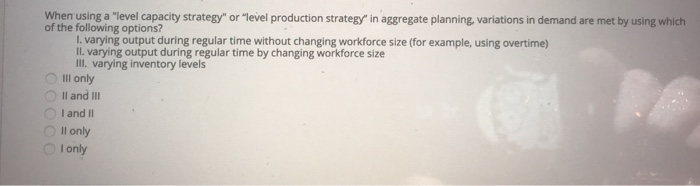

Level Capacity Plan The inventory size is varied keeping the workforce size and utilization of work constant The number of workers (working size) is kept constant throughout the time period under consideration During months of low demand the excess units required over the units produced are taken from the inventoryStrategic capacity planning is essential as it helps the organization in meeting the future requirements of the organization Planning ensures that operating cost are maintained at a minimum possible level without affecting the quality It ensures the organization remain competitive and can achieve the longterm growth planLevel Capacity Plan Definition An approach to mediumterm capacity management that attempts to keep output from an operation or its capacity constant, irrespective of demand Operations Management by Nigel Slack, Alistair BrandonJones, Robert Johnston

Www Kinaxis Com Sites Default Files Resources Capacity planning constraints rapidresponse Pdf

Level strategy for capacity planning

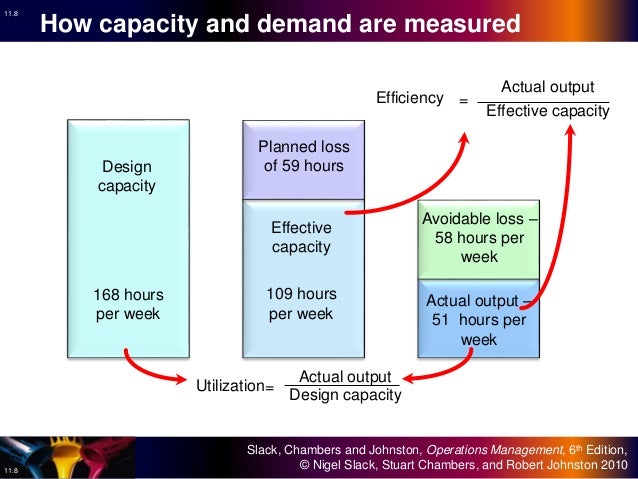

Level strategy for capacity planning-The level capacity strategy involves maintaining stable workforce level and output rates over the planning horizon This allows the firm to maintain inventory levels of finished products higher than expected in situationsFrom Wikipedia, the free encyclopedia Capacity planning is the process of determining the production capacity needed by an organization to meet changing demands for its products In the context of capacity planning, design capacity is the maximum amount of work that an organization is capable of completing in a given period

Ppt Aggregate Production Planning Powerpoint Presentation Free Download Id

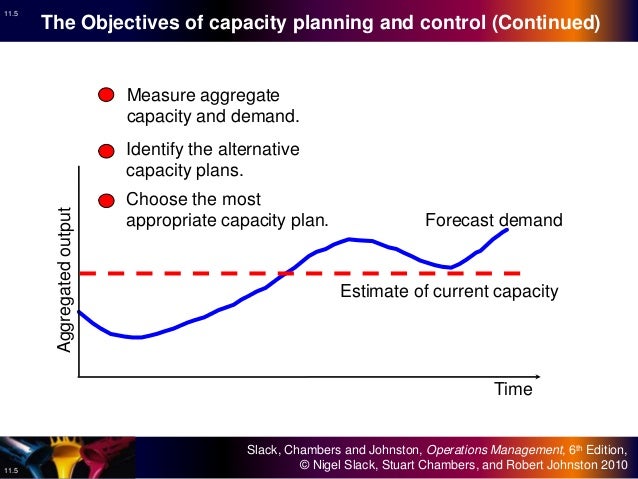

Capacity is usually measured in convenient units such as litres per hour or passengers per taxi For instance, a domestic tap may be able to deliver litres per minute of water;"The level capacity plan satisfies high demand from existing stocks When demand goes below capacity, overproduction is stored as inventory in anticipation of higher demand in later months The disadvantage of this approach is that this tends to build in high stock levels and hence high levels of working capital are requiredUPMC St Margaret Hospital Surge Response Plan 1 11/28/12 LEVEL DEFINITION AND CRITERIA NEDOCS Score and Interpretation LEVEL 1 – 2 NEDOCS = 0 – 60 Not busy busy LEVEL 3 NEDOCS = 61 – 100 Extremely Busy, not overcrowded LEVEL 4 NEDOCS = 101 140 Overcrowded LEVEL 5 NEDOCS = 141 – 180 Extremely Overcrowded Level 6 NEDOCS = 181 – 0

Sep 18, · The level of capacity directly relates to the amount of output in the form of goods and services manufacturers can produce to satisfy customer demand Capacity planning strategies can guide manufacturers on how much raw materials, equipment, labor, and investment in facilities need to be acquired over a period of time to meet the future demand over productsJun 02, · Capacity Planning used in conjunction with an ERP system can improve the accuracy of planning and help control costs as well as plan for future expansion and growth However, because each company is different, there are things to consider when using capacity planning in manufacturing Data Accuracy – Any software platform is only as accurateRemove the vacancy rate for the immediate near term month, but keep for all future months 2

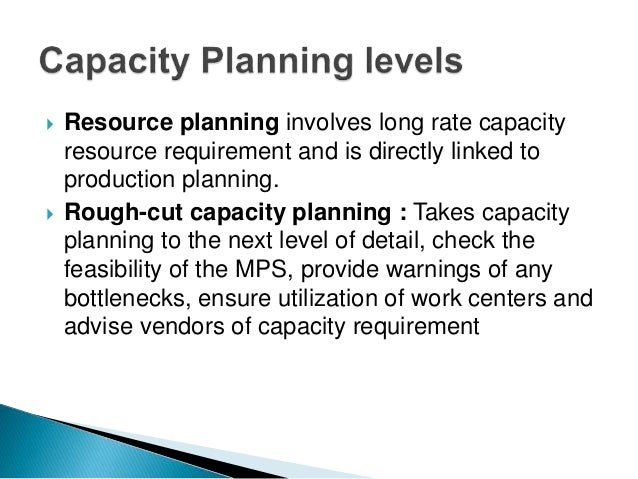

Jun 28, 13 · 32 Example RoughCut Capacity Planning Texprint Company makes a line of computer printers on a producetostock basis for other computer manufacturers Each printer requires an average of 24 laborhours The plant uses a backlog of orders to allow a levelcapacity aggregate plan This plan provides a weekly capacity of 5,000 labor hoursCapacity Planning refers to the arrangement in which organizations or teams match employees together with the needs of a project Capacity is the optimum level of work that can be done within an established period Usually, it is measured in the quantity of work that isThis revision video provides an overview of the concept of capacity, capacity utilisation and some of the issues facing businesses operating at low or high u

Capacity Planning And Control Ppt Video Online Download

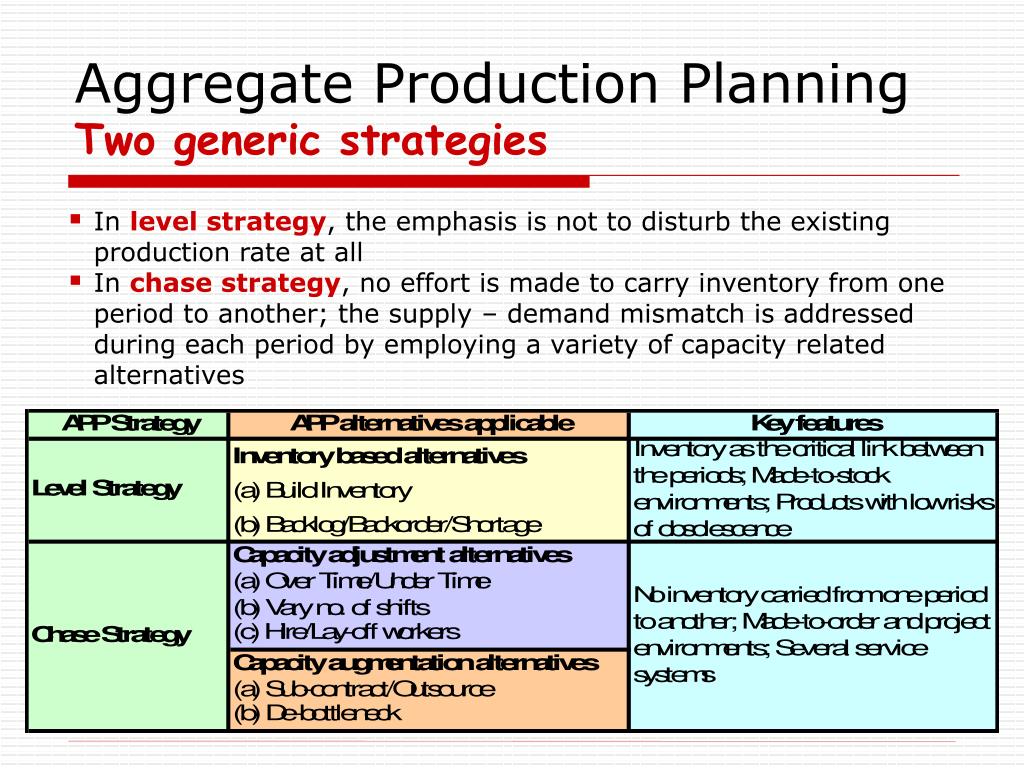

Aggregate Planning Strategy Organization Levels System Examples Model Type Company System

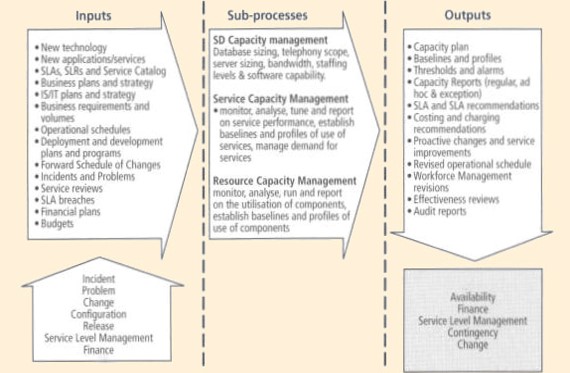

Manager A is in charge of the cashiering operation—theApr 25, 21 · The capacity plan is the important and major output of capacity planning Based on the service level targets and requirements, IT service provider has to meet the targets agreed with the customer or businessThe first is called level scheduling, where you try and maintain a steady workforce with a steady schedule The second is the chase strategy, where you maintain a level workforce and increase your workforce as demand increases This may mean using overtime or hiring temporary employees The type of laborscheduling you wish to incorporate can

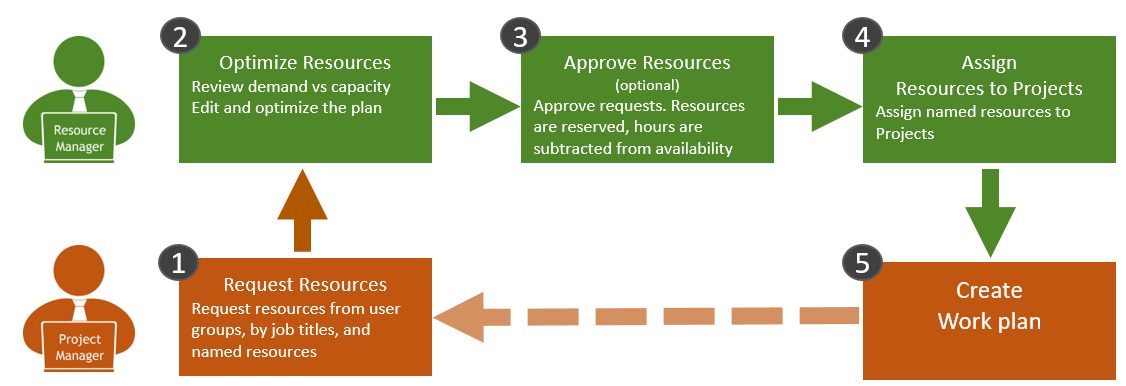

What Is Capacity Planning Examples Types Optimoroute

Elements Of Who Capacity Building Plan 36 Download Table

Easy to Calculate & Plan your scrum team capacity and Sprint in ExcelLink to the template https//agiledigestcom/product/capacitysprintplanningtemplateSep 06, 17 · High level prioritized capacity plan – drag to set priorities 3 The levers you can pull when capacity planning The resource capacity of most organizations is relatively fixed Which means capacity planning mostly involves managing the demands being made on your resourcesA period's planned quantity of output is equal to that period's expected demand Level capacity strategy When an organization adopts the level capacity strategy then it manufactures at a constant output rate It does not consider any fluctuation or change in the level of demand

11 Capacity Planning And Control Operations Management

Capacity Planning Organization System Examples Definition System Long Term Capacity Planning

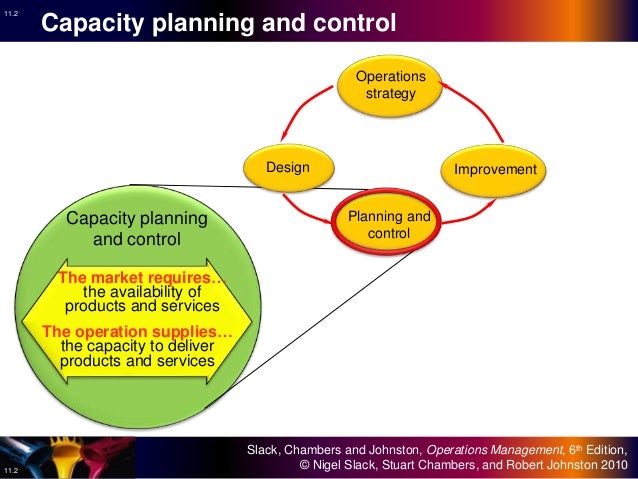

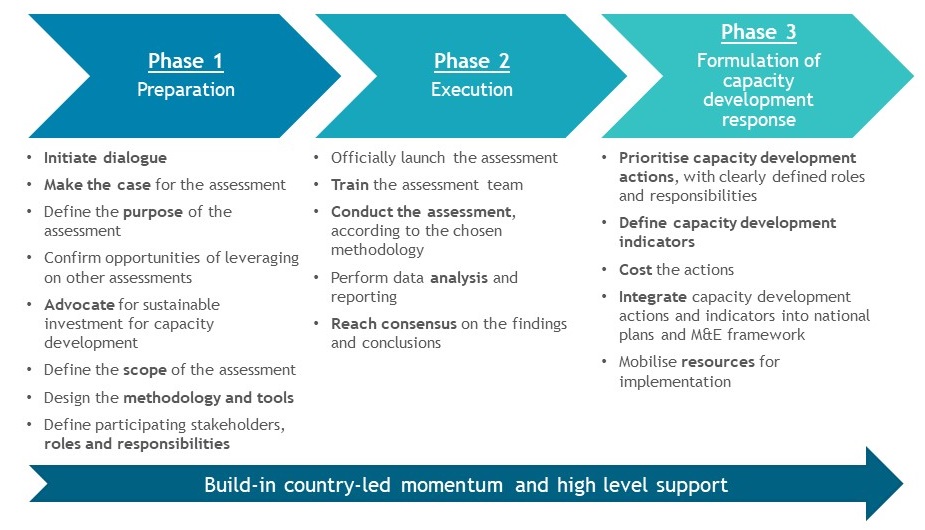

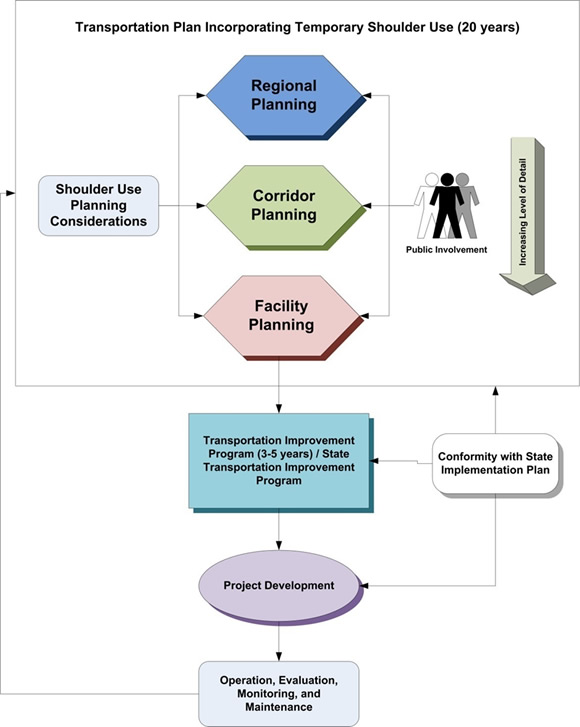

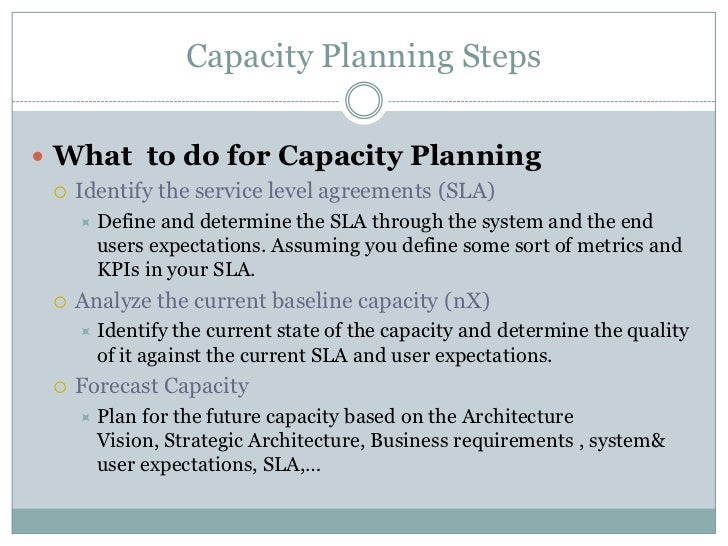

Identify the transforming resources Measure aggregate capacity and demand Identify the alternative capacity plans O Choose the most appropriate capacity planPurpose of Capacity Plan Provide the purpose of the capacity plan For example Capacity planning is an important part of infrastructure and deployment planning A capacity plan supports the goal of optimum, and cost effective, provisioning of organizational resources and services by matching them to business demands1 Collaborate and plan with a variety of community, civic, governmental and private organizations 2 Be familiar with the County's AllHazards Response Plan and the health and medical component presented in Annex G of the plan, which is developed by hospital, local public health, community clinics, mental health resources, and EMS 3

Pdf An Approach To Capacity Planning Of Distribution Warehouses For X Firm Semantic Scholar

Capacity Planning What Is It And How Do I Implement It Projectmanager Com

Capacity is the maximum amount of work an accounting practice is capable of completing in a given period of time Capacity planning is the process of determining the resources (time, people, etc) that the firm needs to meet changing demands for its services – in other words, how it will meet its current and future client needsEach method is based on reacting to or planning for market fluctuations and changing levels of demand These capacity planning strategies are match, lag, lead, and adjustment Match Matching involves monitoring the market for demand increases and decreases on a regular basisCapacity requirement planning forms part of the operational stage of the planning process and works in conjunction with a manufacturing requirement planning (MRP) system A detailed capacity requirement plan provides an operational level overview for the production cell and assists the operations manager with identifying all of the elements

Capacity Planning And Control Ppt Download

What Is Capacity Planning Examples Types Optimoroute

Nov 26, 19 · It looks at the availability of those resources at the skill set/team level Then it facilitates the decisionmaking process to hire resources or defer/approve/cancel projects Capacity planning is about supply and demandA bus may have a capacity of 53 passengers, a football stadium may be able to seat 50,000 spectators or a McDonalds may be able to serve 600 customers per hourI maintain our capacity at a level of 17,000 transactions per day" Why the big difference in capacity management in the same firm?

Entries For Thursday 25 October 07 Sergio S Blog

1

Jan 14, · What is a level capacity plan?Jun 07, 21 · The Maharashtra government's fivelevel plan to unlock the state, based on weekly positivity rate and occupancy of oxygen beds in districts, came into effect from MondayAug 27, 13 · The people managers should own the headcount and timing of position changes To finetune your Payroll and Benefits forecast use a series of adjustment factors 1 vacancy rate ~6% (your company may differ);

Capacity Planning Meaning Classification And Its Goals

Parry Operations Management Managing Capacity Youtube

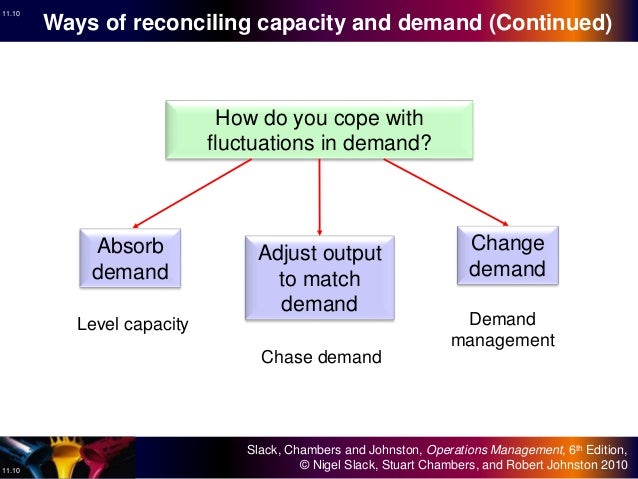

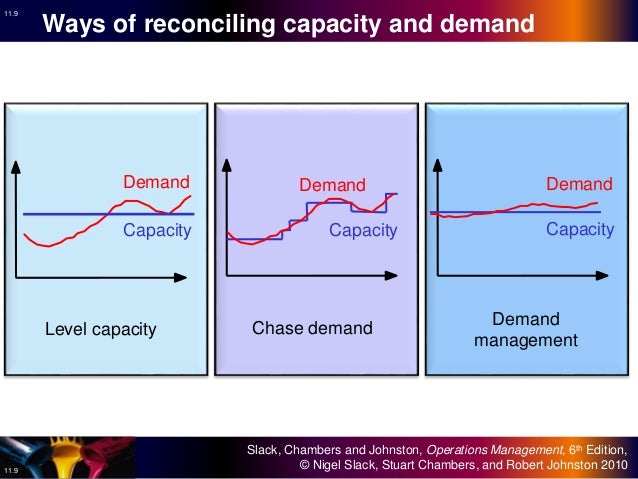

Jul 01, 21 · An approach to aggregate planning that attempts to match supply and output with fluctuating demand Depending on the product or service involved, the approach can incur costs by the ineffective use of capacity at periods of low demand, by the need to recruit or lay off staff, by learningcurve effects, and by a possible loss of quality The advantages include low storageFrom IT Process Wiki Definition The Capacity Plan is used to manage the resources required to deliver IT services The plan contains scenarios for different predictions of business demand, and options with cost estimates to deliver the agreed service level targetsLevelcapacity plan Chase demand plan Demand management plan Emergent plan Flexible plan QUESTION 35 Which one of the following is NOT one of the capacity management steps?

Sales And Operations Planning Aggregate Planning Production Planning

Myclass Dau Edu cswebdav Xid 4 5

Capacity requirements • ASA = average speed of answer Ewait • TSF = telephone service factor (or service level) P{wait ≤ T} • Fraction of calls abandoned before served P{abandon} • Determining capacity requirements for interval i eg Ni = min{N Ewait ≤ ASA∗} 8Capacity planning is the analysis of what you are capable of producing versus what your expected demand will be Capacity planning should take place at multiple levels In order to increase capacity, you may have to purchase new equipment or change facilities This can be aCapacity is outsourcing, in which suppliers absorb the risk of demand uncertainty The best operating level for a facility is the percent of capacity utilization that minimizes average unit cost Rarely is the best operating level at 100 percent of capacityat higher levels of utilization, productivity slows and things start to go wrong

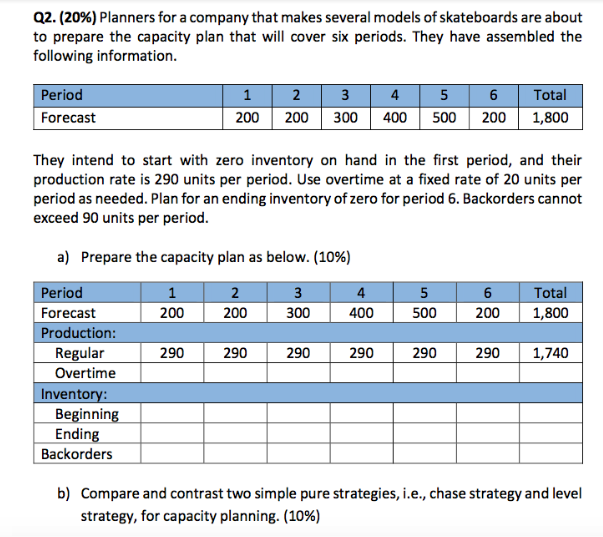

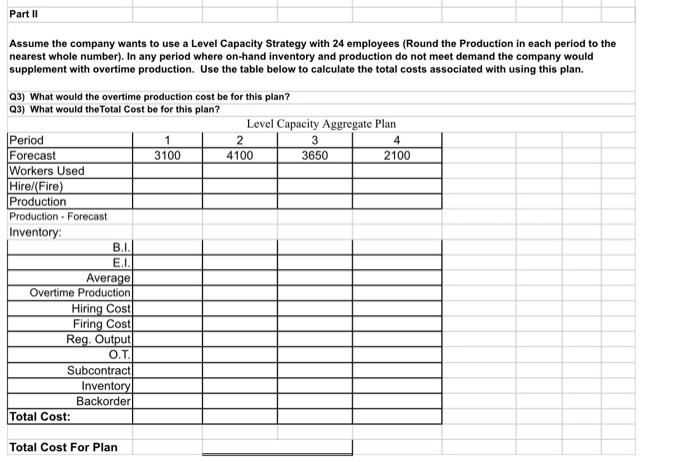

Q2 Planners For A Company That Makes Several Chegg Com

What Is Production Planning Erp Module And Its Features

Sep 14, 17 · 3 Examples of Production Capacity John Spacey, September 14, 17 Production capacity is the volume of products or services that can be delivered by the operational resources of an organization Resources include factors such as land, labor, facilities, infrastructure and machines The following are illustrative examples of production capacityMay 17, 21 · Capacity planning is the practice of planning/determining production capacity and workforce needs to make sure your supply chain is equipped to meet demand Capacity planning lets businesses know how and when to scale, identify bottlenecks, create better design capacity, and mitigate risk, within a planned period of timeA period's planned quantity of output is equal to that period's expected demand Level capacity strategy When an organization adopts the level capacity strategy then it manufactures at a constant output rate

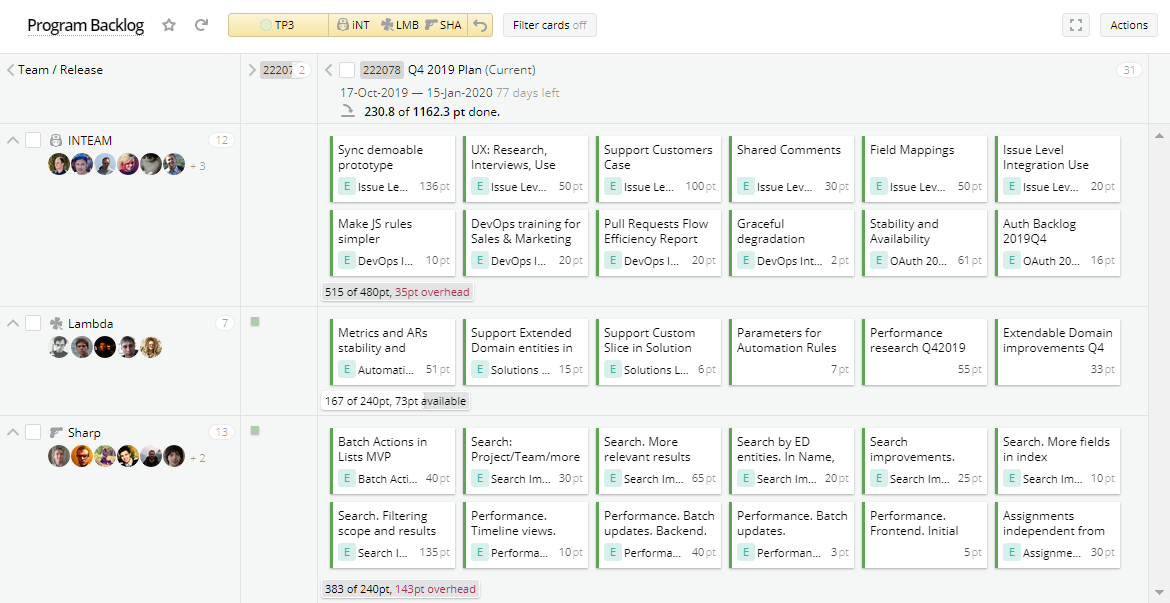

Pin On Agile Project Management

Manufacturings Objectives The Goal Of Manufacturing Is To

5 Capacity Planning For Products And Services Mc

Inputs And Outputs To Aggregate Production Planning Capacity

Capacity Planning Everything You Need To Know Clicktime

Www Kinaxis Com Sites Default Files Resources Capacity planning constraints rapidresponse Pdf

Capacity Management Process Pink Elephant United Kingdom

Nipn Capacity Development Plan Nipn

Parry Operations Management Managing Capacity Youtube

What Is Capacity Planning An Introduction Clarizen Success

Capacity Planning What Is It And How Do I Implement It Projectmanager Com

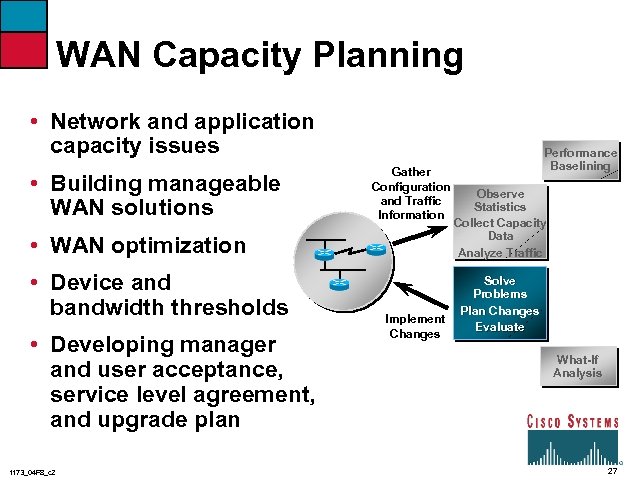

Capacity Planning For Enterprise Networks An Overview Of

Peoplesoft 8 4 Production Planning Peoplebook

Capacity Planning And Control

Study Of Manufacturing System Capacity Planning Control Steps In Capacity Planning Measuring Demand Capacity Yield Management

Data Model And Hierarchy Targetprocess Enterprise Agility Solution

Pin On Itil

How Is Yield Management Implemented In Airline Industry Ayat Saleh

Sap Heuristics

What Is Capacity Planning Examples Types Optimoroute

How To Create Use A Capacity Plan Review Of Optometric Business

Efficient Use Of Highway Capacity Summary Chapter 1 Background Fhwa Operations

1

Capacity Management Objectives Roles Concepts Mitsm

Time Range Strategic Capacity Planning

Capacity Planning And Control Chapter 11 What Is

Solved Question 34 Which Alternative Capacity Plan Relies Chegg Com

Pgbm03 Mba Operation Management Session 06 Planning And Managing Capa

Www Sap Com Docs Download 06 943efecf 9f7d 0010 87a3 C30de2ffd8ff Pdf

5 Masterprodscheduling Inventory Forecasting

Can Capacity Planning Technology Help Plan Labor Budget

5 Steps To Create A Tech Support Capacity Plan The Operations Blog

Capacity Management

Level Capacity Plan Approach Ppt Powerpoint Presentation Summary Cpb Powerpoint Shapes Powerpoint Slide Deck Template Presentation Visual Aids Slide Ppt

High Level Capacity Planning

Ppt Operations Management Powerpoint Presentation Free Download Id

Capacity Planning And Control

Aggregate Planning Chapter 11 Mis 373 Basic Operations Management Ppt Download

Feature Based Capacity Planning Targetprocess Enterprise Agility Solution

Operations Management Lesson 8 Flashcards Quizlet

Www Kinaxis Com Sites Default Files Resources Capacityplanning Ebook 18 Pdf

Capacity Planning And Modelling

Q Tbn And9gcqytvm28phg Flc1jbxscbyoduapoqtpbknwdc60pk3a2805i I Usqp Cau

Solved Part Ii Assume The Company Wants To Use A Level Ca Chegg Com

1

Resource And Capacity Excel Plans 26 Templates Project Management Templates Project Management Tools How To Plan

What Is Capacity Planning Examples Types Optimoroute

Metron Capacity Management Capacity Management Guided Practitioner Satnav Capacity Plan 16 Of 17

Ppt Aggregate Production Planning Powerpoint Presentation Free Download Id

What Is Capacity Planning And How Often Should You Do It

Figure 2 From Hierarchical Capacity Planning With Reconfigurable Kits In Global Semiconductor Assembly And Test Manufacturing Semantic Scholar

Capacity Planning What Is It And How Do I Implement It Projectmanager Com

11 Capacity Planning And Control Operations Management

Pdf An Optimisation Approach For Capacity Planning Modelling Insights And Empirical Findings From A Tactical Perspective Semantic Scholar

Level Capacity Plan Ppt Powerpoint Presentation Pictures Background Cpb Presentation Graphics Presentation Powerpoint Example Slide Templates

Value To The Business Capacity Management Is Responsible For Ensuring That It Resources Are Planned And Scheduled To Provide A Consistent Level Of Service That Is Matched To The

11 Capacity Planning And Control Operations Management

Sales And Operations Planning Aggregate Planning Production Planning Operations Planning How To Meet Effectively And Efficiently Forecasted Requirements Ppt Video Online Download

Capacity Requirement Planning

11 Capacity Planning And Control Operations Management

Level Capacity Plan Level Capacity Plan The Inventory Size Is Varied Keeping The Operation Management

Mastering Resource Capacity Planning And Demand For Optimum Project Performance Katalyst

Level Capacity Plan Approach Ppt Powerpoint Presentation Summary Cpb Powerpoint Shapes Powerpoint Slide Deck Template Presentation Visual Aids Slide Ppt

Mba638 Files Wordpress Com 17 01 Om L5 Capacity Management Pdf

Demand Capacity Modelling And Covid 19 Disease Identifying Themes For Future Nhs Planning Pandit Anaesthesia Wiley Online Library

Aggregate Capacity Planning Pdf Free Download

Models Of Aggregate Planning

Solved When Using A Level Capacity Strategy Or Level P Chegg Com

Implementing A Sales Operations Planning S Op Process Plex Demandcaster

Www Kronos Com Resource Download

A Critical Insight To Successful Supply Chain Planning

Capacity Planning What Is It And How Do I Implement It Projectmanager Com

Advanced Planning And Scheduling Solutions Boost Productivity Applied Materials

Chapter 3 Strategic Capacity Management Ppt Video Online Download

Ppt Capacity Planning Powerpoint Presentation Free Download Id

Essay Utwente Nl 1 Puspasari Ma Mb Pdf

Uninote Ecommerce S3 Eu West 2 Amazonaws Com Capacity management Pdf

Naas Playbook Capacity Planning Telecom Infra Project

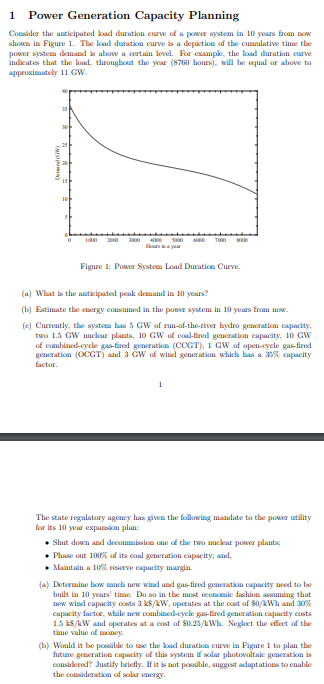

1 Power Generation Capacity Planning Consider The Chegg Com

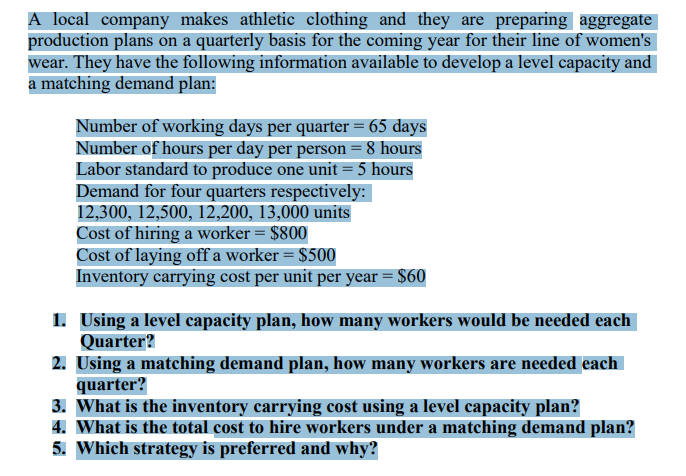

A Local Company Makes Athletic Clothing And They Are Chegg Com

Concept Of The Optimisation Model For Technology And Capacity Planning Download Scientific Diagram

Operations Management Daniel S Blog

Operational Uncertainty Mbaid My Study

Aggregate Planning Mps Capacity Planning Strategic Management Inventory

Capacity After Deciding What Products Services Should Be Offered And How They Should Be Made Management Must Plan The Capacity Of Its Processes Capacity Ppt Download

11 Capacity Planning And Control Operations Management

0 件のコメント:

コメントを投稿